In 2017, Milos utilized their truss manufacturing and design knowledge to create an entirely new line of truss that was launched in 2018, Milos Steel Truss, which satisfies the ever-increasing loading requirements of leading live events across the globe.

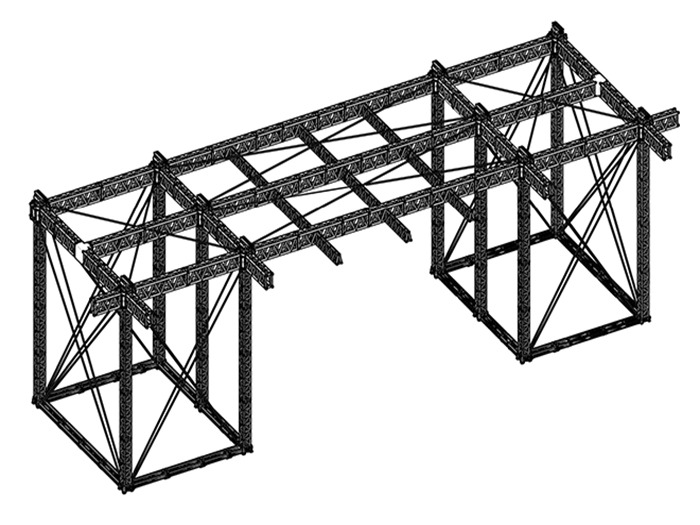

Introducing the Milos PA Delay Tower, Milos LED Screen Support Structure and Milos Pitched Roof. All three structures are made with Ultra High-Strength Steel that takes loading to the extreme.

Key features of the MILOS Steel Truss range:

Full line of tower and ground support components (Steel Base with Outriggers, Sleeve Blocks, Head-Section and the Locking Unit for securing the Sleeve Block against drop AND lift)

Greatly increased span lengths (up to 60m free spans!) and loading capacities compared to aluminium truss.

Special steel alloy that provides a nearly 4x more strength compared to standard S235 Steel.

Integrated forklift pockets for convenient transport.

Durable, industrial black paint finish as standard on all truss and tower sections.

PA Delay Tower:

The MILOS PA Delay Tower provides extreme loading capacity for safely flying your super heavy PA systems without guy wires.

Truss

MILOS S-QTQT Ultra High-Strength Steel Truss (780 x 780mm)

Size and weight capacities

Front face of PA: 10 m2

Side face of PA: 5m2 max.

Loading capacity: 2,500 kg

Wind Loading

Wind loading of secured structure up to 28m/second

Anchoring / Ballast

Due to the use of our integrated steel base with outriggers (3m outriggers at front/back and 2m on each side), combined with the significant self-weight of the Tower (70kg/metre), no ballast, or a very small amount of ballast, is required (maximum of 2t).