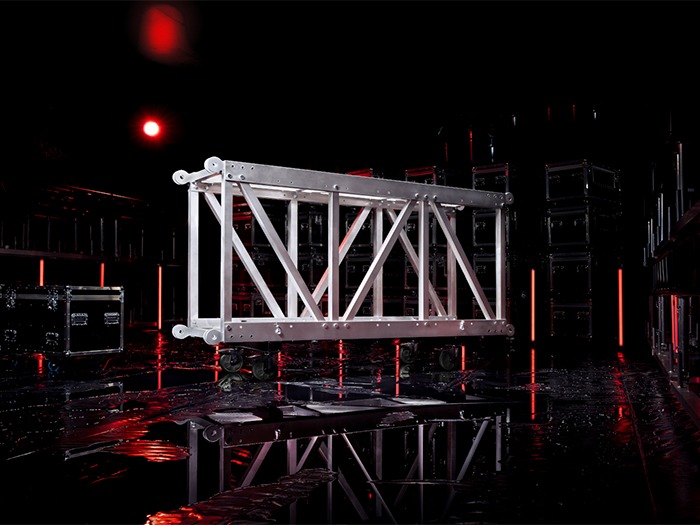

The new Big Boys Toy Truss (BBT Truss) can take a distributed load of 20 tons over a span of 30 metres.

This makes it the strongest aluminium truss in its class and it can carry up to 60% more load than previous comparable trusses.

This is possible by the fact that the Big Boys Toy Truss does not have a single weld and is completely bolted with the patented Ripp Lock Nut System.

At the same time, the BBT offers enormous flexibility with minimal volume: since there are no welded parts, damaged bracing can be replaced directly at the venue. This saves costs and time.

The Big Boys Toy Truss is available with 3 different bracing sets – depending on the load requirements, the appropriate bracing can be installed. The BBT is thus buildable in heights of 1400mm, 1200mm and 800mm.

The truss can be dismantled very easily if required, and thus offers an incredibly low transport volume: up to 150 metres of truss can be transported with only one truck. This results in a 50% reduction in transport volume, which in turn leads to considerable savings in transport costs and CO2 emissions.

On an average European tour with 30 cities, this results in a saving of 44 tons of CO2. The BBT is available in lengths of 2 metres, 3 metres, 4 metres and 6 metres.

HOF also manufactures special lengths and special heights upon customer request.